10ft Sheet Metal Brake 20 Ga.

It is also known as a bending machine or bending brake or in Britain as a sheet metal folder or just a folder . Description The brake consists of a flat surface onto which the material is placed, and a clamping bar which will come down and hold the material firmly during the bend.

Hydraulic Sheet Metal Bending Brake 63T

Phillip Thomas. We've poked at bending sheetmetal in a previous installment of Wrenchin' Wednesday, but today we're going to talk about how to build your own sheetmetal brake for the sake of getting crisp, precise edges on custom-fabricated parts.Hammering metal around a form is effective, but can leave behind apprentice marks, leave an inconsistent edge, or just be a flat-out pain in.

Sheet Metal Bending Brake Woodworking Project Woodsmith Plans

How to make a DIY Sheet Metal Bending Brake Fullboost 469K subscribers 406K views 8 years ago In this episode of the fullBOOST tech files we show you how to make your own DIY bending brake. A.

Sheet Metal Bending Brake Woodworking Project Woodsmith Plans

Metal Brakes Free Shipping In Stock My Saved Products Metal Brakes Items 1 - 24 of 70 Sort By Eastwood 48 Inch Electro-Brake Sheet Metal Brake Reg. $ 2,999.99 Sale $ 2,699.97 Save $ 300.02 Add to Cart Eastwood Versa Bend Sheet Metal Brake Reg. $ 259.99 Sale $ 239.97 Save $ 20.02 Add to Cart Eastwood 12 Inch Box and Pan Sheet Metal Brake $ 377.99

48" Box and Pan Brake 16 Gauge Bender Sheet Metal Bending Machine

Sheet metal brakes are machines designed to make bending thin metal into shapes for use in projects such as house siding, eaves, air conditioning ductwork, and others. [1] This project will help you build a simple sheet metal brake for bending small work for those who prefer to do it yourself. Steps Download Article 1

24Inch Sheet Metal Bending Brake W1.2x610 KAKA INDUSTRIAL LTD

Need to bend sheet metal? Making one yourself is cheap & easyNext episode we are tackling a new project that requires a metal brake, off the shelf machines a.

Brakes & Benders 36 Inch Sheet Metal Bender Bending Brake With Stand

This process requires specific sheet metal bending machines or press brakes, which exert pressure on the metal, ensuring accuracy and consistency. The bend's angle is determined by various factors, including the type of metal, its thickness, and the desired bend radius. The beauty of this process lies in its versatility.

Press Brake Tooling Enables High Quality Sheet Metal Forming Metal

The standard procedure for making a simple bend in sheet metal using a hand brake machine is as follows: 1. Insert sheet metal under clamping bar. 2. Adjust clamping handle cam for metal thickness. 3. Measure and position the sheet metal edge the correct distance parrallel to the clamping bar. 4.

Woodward Fab Sheet Metal Bending Brake

Sheet Metal Brakes sheet metal brakes Box and pan brakes or finger brakes have removable fingers to allow complex bending not attainable with straight brakes. Find the working length and gauge capacity that best fits your needs. BRAND Narrow by Sub Category Straight Brakes Box & Pan Brakes Press Brakes Radius Brakes Magnetic Brakes See All Products

DIY Sheet Metal Bending Tool Sheet Metal Brake YouTube

1 Gather your materials. Having the right tools on hand will help this process go smoothly and quickly. To bend your sheet metal with a vise and hammer, you will need: 2 wooden or metal form blocks Block of hardwood and heavy-duty hammer or mallet (optional) Calculator or online bend calculator Marker Protractor Rubber, plastic, or rawhide mallet

Hand Brake MB36, 36 Inch 20 Gauge Sheet Metal Bending Brake KAKA

The performance of rail transport has increased significantly in recent decades, in particular due to the gradual introduction of high-speed rails worldwide. In 1981, the first high-speed line of the world was inaugurated; nowadays, high-speed is operating in more than 20 countries, the high-speed network covering more than 35,000 kms (with more than 25,000 additional kms under construction).

Erie Tools 4" Hand Bending Brake & Sheet Metal Form Bender Pressing Die

This Ironton® 18in.W Sheet Metal Bending Brake is a sturdy, professional-quality bending brake that's ideal for bending heavy foils and light gauge metals or for forming acrylics and plastics. The brake is compact and lightweight yet sturdy enough for professional production runs. The design allows for a full 90° capacity in steel as thick as.

36" High Precision Brake Heavy Duty Sheet Metal Bending Brake 20 Gauge

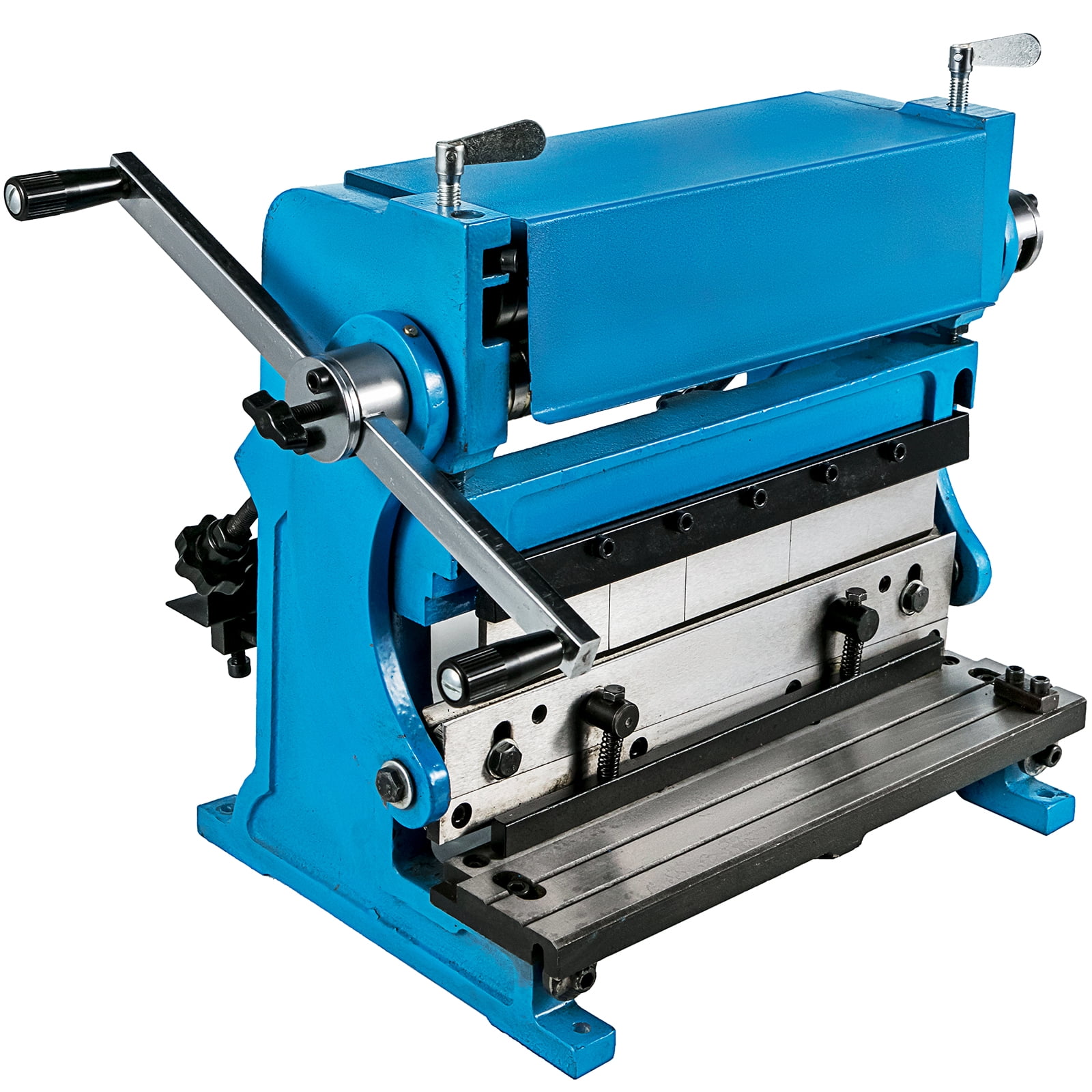

Save space in your shop by cutting, bending, and curving sheet metal with a single machine. Also known as shear brake rolls. Use the blade on the shear to make clean, straight cuts; it has two cutting edges for twice the life. A press brake makes bends up to 90°. Create curves and circles with the slip roll.. When using the shear or press brake, set the manual back gauge to precisely position.

VEVOR Sheet Metal Brake 3In1 12inch,Shear Press Brake 20Gauge

TBR - Ep. 051 - Breaking Bad New tool day! This one we're making ourselves like a true Jedi. Violet Crumbles needs a long piece of metal bent up to repair t.

DIY Metal Brake for Bending Sheet Metal YouTube

Our metal bending brakes are perfect for bending 14 Gauge mild steel. These metal bending brakes are robust, precise, and built to last. It will suit any machine shop looking to add a reliable and heavy duty straight sheet metal brake in any industry. If you're in the HVAC, roofing, automotive, or food truck industries and looking for the best.

W1818 18" 20 Gauge Mini Sheet Metal Bending Brake KAKA INDUSTRIAL LTD.

What is a sheet metal brake A brake is a metalworking machine that allows the bending of sheet metal. A cornice brake only allows for simple bends and creases, while a box-and-pan brake also allows one to form box and pan shapes. It is also known as a bending machine or bending brake or as a sheet metal folder or just a folder. Cornice brake